Dynamics 365 Business Central helps to respond to various demands from multiple business sectors and supports handling of different currencies, empowering users to set up and manage numerous bank accounts.

On Premise

On Premise

Cloud

Cloud

Microsoft dynamics 365 business central Modules

This module deals with all the Financial Transaction that we carry out in a company. The functionalities include, but are not limited to, G/L budgeting, financial reporting, cash management, receivables and payables, fixed assets, VAT and tax reporting, intercompany transactions, cost accounting, consolidation, multicurrency, intrastate, and more.

The chart of accounts displays all the accounts (balance sheet accounts and income statements accounts) used to post transactions to the general ledger. Apart from default setup, advanced features for VAT or tax processing can be used. It is possible to define dimensions and add values in entries, which leads to increased report accuracy, as well as to create custom general ledger accounts. Such accounts are used in sales and purchase documents, and in general journals for posting transactions in the general ledger.

Dynamics 365 Business Central provides enhancements in the area of payment processing. You can enter and manage the payment on the same page. The option of marking your invoices as paid and running automated account reconciliation is just a few clicks away. The payment journal, covering advanced features such as vendor priority setup and payment due dates, is used to settle payments for vendors, as well as to process and reconcile bank statement transactions at the same time. To process payment reconciliation, run the suggest vendor payments batch. Payments can be made electronically or by check, if needed, after modifying the payment journal lines. To do this, simply import bank statement files and transactions will be settled automatically, in accordance with all the advanced rules that you have defined.

For companies, to ensure a deeper insight into cash availability, improved cash flow forecasting is a must. As part of Dynamics 365 Business Central, the cash flow forecast functionality enables users to calculate estimated cash flows. A variety of cash sources can be considered, such as sales orders, purchase orders, receivables, payments. The system analyses the possible implications of planned loans or investment based on expense and revenue information. With in-built Cortana Intelligence and machine learning tools using historical revenues and expenses, users can generate cash flow forecasts.

Users can take advantage of budgeting features that are available for costs, sales, purchases and general ledger accounts.

Once the appropriate setup is complete in Dynamics 365 Business Central, dimensions can be used in complex financial analyses. Default dimensions can be assigned to customers, items, vendors, G/L accounts, jobs or resources and numerous dimension values can be created for each dimension defined. For example, a customer group dimension can be assigned to a sales document before posting a sales transaction. A department can be assigned when posting expenses in order to facilitate the analysis and comparison of expenses in regard to specific departments.

The system provides the ability to set up deferral templates that allow users to automate the deferral settlement process for revenues and expenses, in compliance with a predefined schedule.

You can get an in-depth look into the fixed asset management by monitoring fixed asset transactions, such as appreciations, disposals, acquisitions, depreciations and write-downs.

With Dynamics 365 Business Central, it is possible to assign audit trails and transaction posting descriptions automatically. Furthermore, users can set up customized reason codes that are used to create additional audit trails.

Dynamics 365 Business Central helps to respond to various demands from multiple business sectors and supports handling of different currencies, empowering users to set up and manage numerous bank accounts.

This module handles with planning of material production in a company. The Planning team will be producing the finished goods considering the customer requirement and Production forecast. The production works in a company are also carried out in this module. Manufacturing module includes product design, bills of materials, routing, capacities, forecast, production planning, production order, costing, subcontracting, and many more.

Bill of Material is a list of components required to produce a final product or semi-finished product and contains a description of all components, their quantity and units of measure. The routing specifies a sequence of operations that must be performed to produce a finished product. Capacity setup is used to define a template for a production environment. In Dynamics 365 Business Central, three types of production capacities can be defined for the three production units: production department, work center and machine center.

To manage the processing of purchased raw materials into final product and monitor relevant data, production orders can be used. Production orders store information concerning the types and quantities of products to be manufactured, components, routing steps or operations required to process components into finished products as well as the work and machine centers where routing operations are performed. Work and machine centers represent available capacity.

Production orders are processed until they are completed. The manufacturing process involves actions such as starting a production order, picking up components from the warehouse, using raw materials, manufacturing a product, registering consumption and the final product in the production journal (optionally), and storing finished products in a warehouse.

The demand forecasting functionality enables you to anticipate any type of demand. Users can easily convert forecasts into production plans and reconcile them against the actual sales. The changes in the forecast are also reflected in the existing production plans.

The system offers three production planning options:

• Sales order planning – a simplified planning function that is used to create production orders directly from sales orders. It is recommended for companies manufacturing items for specific orders in the MTO (make-to order) process. In the MTO process, component planning is minimized.

• Order Planning – a more advanced ERP modules that enables you to respond to the demand in multiple demand sources by creating various types of shipments. The program calculates demand without any supply for subsequent orders. With the planning tools, the planner can effectively combine and adjust supply planning, taking into account all other critical factors.

• Planning Worksheet – it can be used to generate the production plan by calculating a complete plan for replenishing the inventory or net requirement, including all information about demand that is available in the system and supplies that cover this demand. The planning mechanism is used for the main production schedule (MPS).

To estimate shop loading, you can compare the requirement to the actual capacity of a machine center. In monitoring and managing shop loading, the system optionally uses the two assumptions:

• Shop loading with unlimited capacity – the system plans production regardless of the shop loading;

• Shop loading with limited capacity – the system plans production orders for a defined capacity percentage.

As resource shortages may occur in manufacturing, capacity planning features are of primary importance. With Dynamics 365 Business Central, it is possible to plan production and capacity calendars for work and machine centers and monitor all scheduled capacity absences.

Nowadays, it is more and more common for manufacturing companies to subcontract some of their orders. Thus, the software that incorporates the subcontracting features is a prerequisite. Microsoft Dynamics 365 Business Central provides powerful tools for managing quantities and costs as part of a typical workflow. The solution supports the entire subcontracting process by enabling the setup integration for work centers, production orders and purchase orders.

The human resources features allow you to register and keep track of detailed employment information, such as work contracts, confidential data, qualifications and other relevant data. The module is used to record employees’ absences and analyze registered absences, if needed. It is possible to record and monitor employees’ expenses by using employee ledgers and the suggest employee payments functionality in the payment journal.

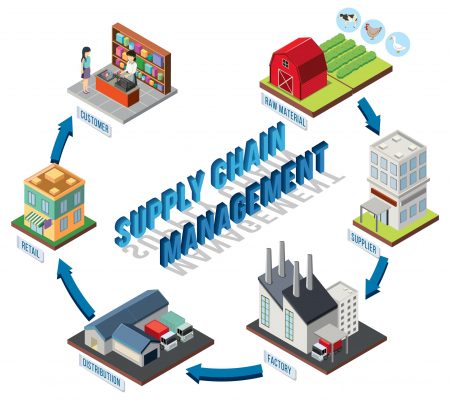

This module deals with Supply chain Management that is purchase of materials needed for production of the finished goods. Purchase module is required when you buy goods and services and you want to keep track of what you have ordered from your vendors and when the goods should be delivered to your door, so you can make the stuff or ship the stuff to your customers. This includes vendors, order processing, approvals, planning, costing, and many more.

This provides a number of functions to configure a broad spectrum of sales and purchase documents that best respond to your business needs. You can set up and use sales/purchase orders, blanket sales/purchase orders, and sales/purchase order processes and automatically assign special prices and discounts to selected customers or customers groups if certain conditions (minimum quantity or order date) are fulfilled. If so, the best price and the highest discount for a customer are granted. As sales order registration is not required, the invoicing process is quick and simple. Moreover, you can define prices and discounts in a sales document for specific lines and set up an invoice discount, which means that the discount percentage is linked to the document amount.

In Dynamics 365 Business Central, the automated workflow is used to monitor and control the entire purchase process. The workflow process involves document entry and registration of paper documents by means of the OCR functionality. Based on notifications about available inventory and availability forecasts, replenishment orders are created. Prices and discounts are granted, if criteria agreed upon with vendors such as minimum quantity or order date, are met. Implementing advanced workflow and approval structures helps you enhance control over purchase costs and expenses.

Sales processes can be managed effectively if efficient tools to track item availability in multiple locations over time are put in place. In the case of stock shortages identified while processing sales orders, Dynamics 365 Business Central generates appropriate notifications, so you can intervene immediately – create a replenishment order or offer a substitute item.

Dynamics 365 Business Central enables you to set up and offer customers non-stock items, i.e. items that have not been registered in the inventory. You just need to fill in a few fields with relevant information. After that, even though the item is not available in stock, you can include it in the price list.

A new item is automatically created on the non-stock item card using the item card template, if a non-stock item is added directly to a sales document. The non-stock item template contains all the fields that are typically set up for an item.

Machine learning in Dynamics 365 Business Central combined with predictive analytics tools ensure precise sales and inventory forecasts based on historical data in specific periods and sources. If stock levels are reduced to zero, a replenishment order can be created just in the forecast chart.

The solution provides features to create and offer substitute items for all items. To setup a substitute item, simply create a link between similar items. If the requested item is not in stock, take a look at all the substitute items and choose one to complete the customer’s order.

Dynamics 365 Business Central supports handling of warehouse receipts, warehouse shipments, put-aways and transfers. Inventory picks are used in assembly, manufacturing and shipment processes.

Inventory management relies on bins that helps track inventory transfers including pick-ups and put-aways. It is easier to optimize inventory consumption, if transfer information is always on hand. The warehousing functionality also facilitates the assembly of items for sales orders and warehouse orders.

The inventory tracking functionality empowers users to collect information about locations where an item was moved, as well as its value in transit and at subsequent locations in the transfer process.

With Dynamics 365 Business Central, users are well equipped to manage inventory in various locations such as warehouses, production plants, distribution centers, showrooms, retail outlets, or service cars.

Project management module helps in tasks such as such as configuring a job and scheduling a resource, as well as providing the information needed to manage budgets and monitor progress. You can track machine and employee hours on the project by using time sheets. As a project manager, you have a good overview, not only of individual jobs, but also of the allocation of employees, machinery and other resources being used in all projects.

A resource is a person or a device that can be tracked individually or as part of a resource group. The resource functionality helps to group resources and record resource prices and sales. Resource management and jobs functionality are often used in tandem.

In Dynamics 365 Business Central, the resource management is handled based on a capacity defined by the user. By tracking the resource usage, you can gain a comprehensive overview of both the capacity and availability of resources.

The job functionality is essential for registration of resource and material usages on specific jobs. The same data is required to generate invoices. However, in invoicing both – fixed-price jobs and time and-material usage may be considered. The functionality helps optimize typical tasks related to project management such as job setup, resource planning, budget management and job progress tracking. It also provides tools for managing long-term projects, recording the manhours and machine hours used, as well as monitoring the consumption of inventory items. Users can also obtain precise data about individual jobs, as well as the allocation of employees, machines, and other resources used in all projects.

A job card stores all the information that is necessary to manage the job from an administration and financial point of view. The actions the job involves are defined as tasks. For each task, you can set up capacity and sales, taking into account the resources and inventory usages. By applying the cost and price of items or resources used for the job, the system calculates actual job budgets, which ensures you can monitor the profitability of a job. When working on a job, you can post item usage as soon as the items are purchased, by assigning a job number and task number in the purchase line, purchase order and purchase invoice. For resources and stocks, the usage is recorded and posted in job journals. To invoice a job, you need to set up an invoicing period. Job statistics provide you with an overview of job costs, enabling you to stick to the budget. The job functionality supports many types of services and consultancy tasks.

Time sheets provides a simple and flexible tool that facilitates the registration of time worked and the approval of time consumption by approvers. Time sheets are integrated with the service, job and resource functionalities and allow employees to enter the time spent on specific projects. They are managed by a timesheet administrator who appoints employees responsible for filling in time registration data. To set up time sheets, the administrator uses job planning lines. The employee is only required to confirm if the time worked on a job or task is the same as the budgeted time. After entering or confirming the hours worked by an employee, the time sheet is sent for approval. The time sheet administrator or project manager can post the time consumption for a relevant task. Upon approval, all expenses and sales revenues are posted in the profit and loss account, whereas work in progress is included in the balance sheet. For this purpose, a valuation method has to be set up. Several valuation options e.g. progress, are available in the application. The job card provides the ability to easily track the work- in-progress status as well as the approved costs and sales.

The Service Management functionality can be used only in the Premium licensing model and supports the whole service process, including service and product supply chains and the delivery of services such as repairs. With Service Management, users can quickly and effectively carry out a number of tasks, such as responding promptly to service requests, planning and scheduling repairs, tracking repair statuses, monitoring and invoicing repair costs, handling warranties, setting up and using service contracts, optimizing inventory levels for spare parts, and improving spare parts for costing.

Service item management functions are the key components of the Service Management module. The equipment or items that need to be serviced or repaired can be defined as service items. The functionality helps you record and keep track of all your service items data including contract information, component management, BOM reference and warranty information.

Service orders are created for equipment or services and they are used to record any maintenance activities or submitted repairs. Service requests can be initiated by the customer or created automatically according to the terms set out in your service agreement. Call center employees or your repair shop can be responsible for service order data entry.

In Dynamics 365 Business Central, to register services as service orders, it is important to plan them first. During the planning process, job tasks are assigned and distributed between employees. While selecting the optimal planning setup, factors such as regional zones, staff skills, and priorities are taken into account. The solution also comes in handy when managing information about service teams and technicians, and filtering data according to several criteria (e.g. availability, skills and warehouse inventory).

Service terms and conditions, as well as performance of all contract – related activities are managed by the contract provisions. With the contract management module, you can register an agreement setting out the required service quality, manage information concerning contract history, contract renewal and contract templates and also generate contract quotes. The system also registers all detailed information service quality, response times, and discount levels, and the service history of each contract, including used service items and parts and labor hours.

The Service Management module empowers users to manage warranty information concerning service items, spare parts, response times, discounts and service levels.

The functionality enables users to define, maintain and monitor service prices. Users can also set up price calculation structures with all the parameters related to service delivery.

The warehouse Module in Microsoft Dynamics 365 Business Central deals with all the Storage of Materials, Material Issue To The Production Dept, Inward and Outward, etc.

This module contains Vendor Card, Customer Card and all the order windows like Purchase Order, Purchase Return Order, Sales Return,Sales Return Orders, Transfer Order, Released Prod. Orders.

Handles with Items, Non-Stock Items, Stock Keeping Units(SKU),Shipments, Put away & Pick Work Sheets, Movement Work Sheets etc.

ie, It mainly handles with Item Stock Management functionalities.

Here You can Manage Inventory Put away & Pick Worksheet and Reclass the Item. i.e., handles Item Movement.

Handles Put away, Pick,Movements and Whe. Item Journals.

In the inventory module handles all the Stock Journal like activities like Item Journals, BOM Journals, Item Reclass Journals, Physical Inventory Journals,Revaluation Journals and Physical Inventory Counting Periods.

This modules handles all the Inward and Outward Gate Entry details.

In this modules you will get all the posted documents information. i.e., if you want to take the GRN(Goods Receipt Note) Print-then you have to go to this place.

The Setup module in Warehousing deals with all the warehouse related setups. This is mainly divided in to 3.

You can create new locations or handles the setup each locations is handles here.

The human resources features allow you to register and keep track of detailed employment information, such as work contracts, confidential data, qualifications and other relevant data. The module is used to record employees’ absences and analyze registered absences, if needed. It is possible to record and monitor employees’ expenses by using employee ledgers and the suggest employee payments functionality in the payment journal.

Project Management